Lihexal 2

Single wire

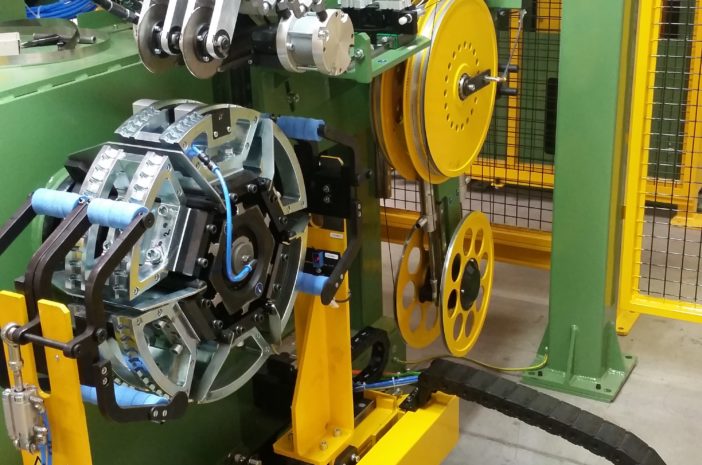

Single Wire Double Head Bead Winding Line

Fully automated process of bead wires production enables to produce 2 products in one cycle what reduces costs of produced bead and thus increases effectiveness of the production. The system is operated and controlled by the computer. The process of production is fully automatic and only one operator is required for the line´s operation.

Specification

- Number beads per cycle:

- 2

- Inside bead diameter:

- 13‘‘ – 26‘‘ / 23‘‘ - 60‘‘

- Max. bead size:

- 19 wires wide x 19 wires high

- Blank wire diameter:

- 1,60 - 1,90 mm

- Bead taper base:

- 0°- 15°

- Inside bead diameter setting:

- ± 3 mm

- Cycle time:

- 16‘‘ – 23,5 s (50 rotations)

- 18‘‘ – 27,3 s (60 rotations)

- 24,5‘‘ – 34,3 s (80 rotations)

Advantages

- One Operator Only

- Production of Hexagonal and Square Beads

- Production Controlled by Recipes

- High Productivity

- Automatic Take off and Stacking

- Adjustability of Bead´s Diameter ± 3 mm

- Simple Adjustability of the Machine including Extruder´s Head Operation

- Computer Controlled Process

- Minimum Interference of the Operator into the Production

Main parts

- Let off stands

- Wire welding unit

- Feeding conveyor of rubber compound

- Extruder for rubber coating of wire

- Temperature Control units

- Taking-off stands and wire festoon

- Bead winding station

- Main electrical cabinet & control system

Options

- Wire pre-heating unit

- Beads storage unit

- Unloading manipulator