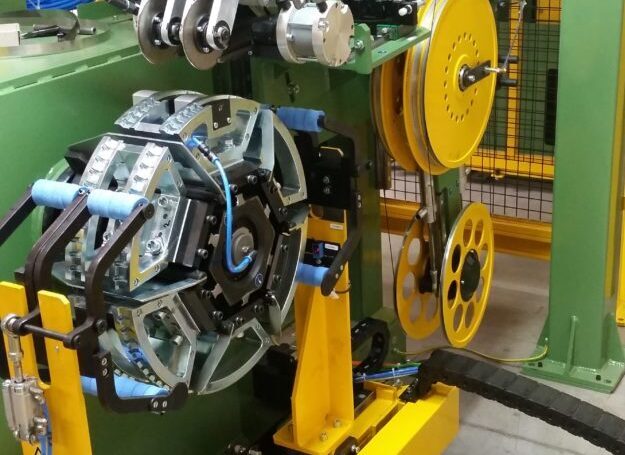

SINGLE WIRE DOUBLE HEAD BEAD WINDING MACHINE

The line is fully integrated system designed for the simultaneously manufacturing of two hexagonal or pentagonal

beads per cycle from a rubber coated wire. The latest generation of HW & SW solutions of the machine

ensure high quality production of beads for tire industry. The line could be equipped with automatic system for

beads handling and storing by robot into beads carriages.

| Number beads per cycle: | 2 |

| Inside bead diameter | 13" - 24,5" |

| Max. bead size: | 19 wires wide x 19 wires high |

| Blank wire diameter: | 1,60 – 1,90 mm |

| Rubber coating thickness:: | 0,20 – 0,35 mm |

| Bead taper base: | 0°- 15° |

| Inside bead diameter setting: | ± 3 mm |

| Cycle time: | 20‘‘ – 27,5 s (51 rotations) 22,5‘‘ – 33 s (62 rotations) 24,5‘‘ – 39 s (79 rotations) |

- PLC and recipe driven production

- Simply operation and machine setup by one operator

- Production hexagonal and square beads

- Automatic bead unloading and storage

- Collection and storage production data

- Let off stands

- Extruder

- Temperature Control units

- Taking-off stands and wire festoon

- Bead winding station

- Beads storage unit

- Main electrical cabinet & control system

- Wire welding unit

- Wire pre-heating unit

- Feeding conveyor of rubber compound

- Rubber coated wires measuring unit

- Automatic beads unloading equipment into trolley