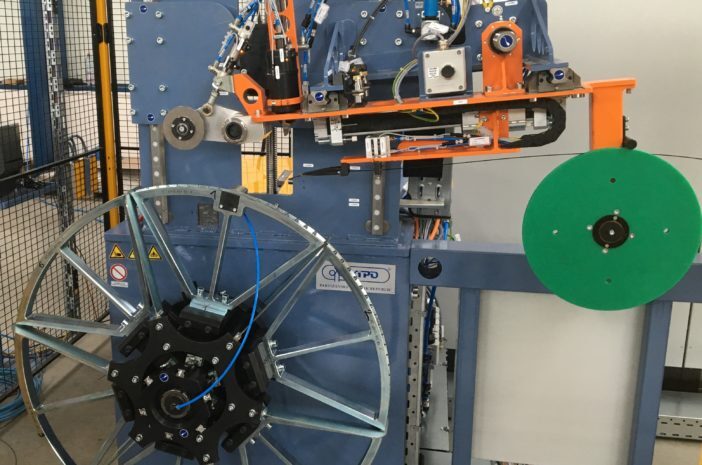

SINGLE WIRE SINGLE HEAD BEAD WINDING MACHINE

The line is fully integrated system designed for the manufacturing of hexagonal or square bead from a single

rubber coated wire. The latest generation of HW & SW solutions of the machine ensure high quality production

of beads for tire industry.

| Number beads per cycle: | 1 |

| Inside bead diameter for PCR/TBR: | 13" - 24,5" |

| Inside bead diameter for OTR/AGRO: | 20‘‘ - 63‘‘ |

| Max. bead size: | 19 wires wide x 16 wires high |

| Blank wire diameter: | 0,89 – 2,00 mm |

| Rubber coating thickness: | 0,15 – 0,35 mm |

| Bead taper base: | 0°- 15° |

| Inside bead diameter setting: | ± 3 mm |

| Cycle time: | 24‘‘ – 48 s (39 rotations) 38‘‘ – 67 s (43 rotations) 50‘‘ – 114 s (60 rotations) |

- PLC and recipe driven production

- Simply operation and machine setup by one operator

- Production hexagonal and square beads

- Automatic bead unloading and storage

- Collection and storage production data

- Let off stand

- Extrude

- Temperature Control units

- Taking-off stand and wire festoon

- Bead winding station

- Main electrical cabinet & control system

- Wire welding unit

- Wire pre-heating unit

- Beads storage unit

- Feeding conveyor of rubber compound

- Rubber coated wire measuring unit