MONO APEX – PCR

Bead Apexing Machines

Bead Apexing Machine for Passenger Tires

Bead Apexing Machine represents set of equipment required for the production and direct application of hot apex profile on bead wire. The main advantage of the line is simple apex application toolins and automatic stacking of apex beads into the plastic separators what prevents from mutual stickiness of beads between them. The whole machine is recipe driven system of integrated units into one line operated by one operator.

Specification

- Bead range diameter:

- 12-18‘‘ / 15‘‘-20‘‘

- Apex height:

- 14 - 50 mm

- Apex width:

- 5 - 13 mm

- Cycle time:

- 1 bead (13" - 16") - 8 s

Advantages

- Automatic application od apex profile

- High machine productivity

- Automatic apexed beads storage unit

- One operator

- Recipe driven system

Main parts

- Mono Apex Extruder

- Feeding conveyor with metal detector

- Temperature control units

- Take off and shrinkage conveyor

- Cooling drum with external chiller

- Apex profile compensator

- Beads storage and transferring system

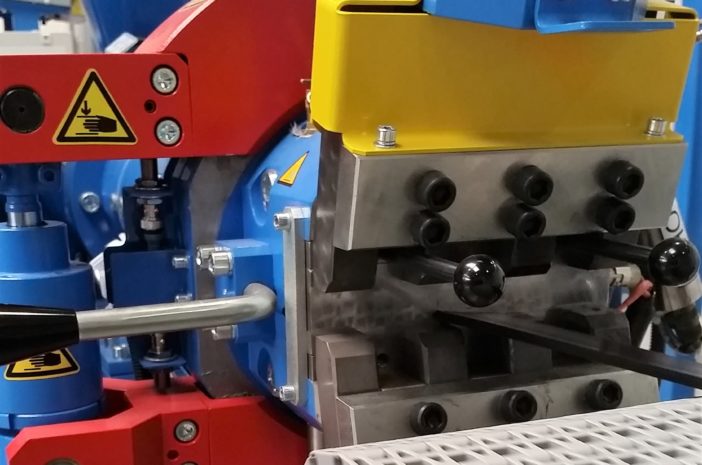

- Apex profile applicator

- Apexe beads storage system

- Main electrical cabinet with control system